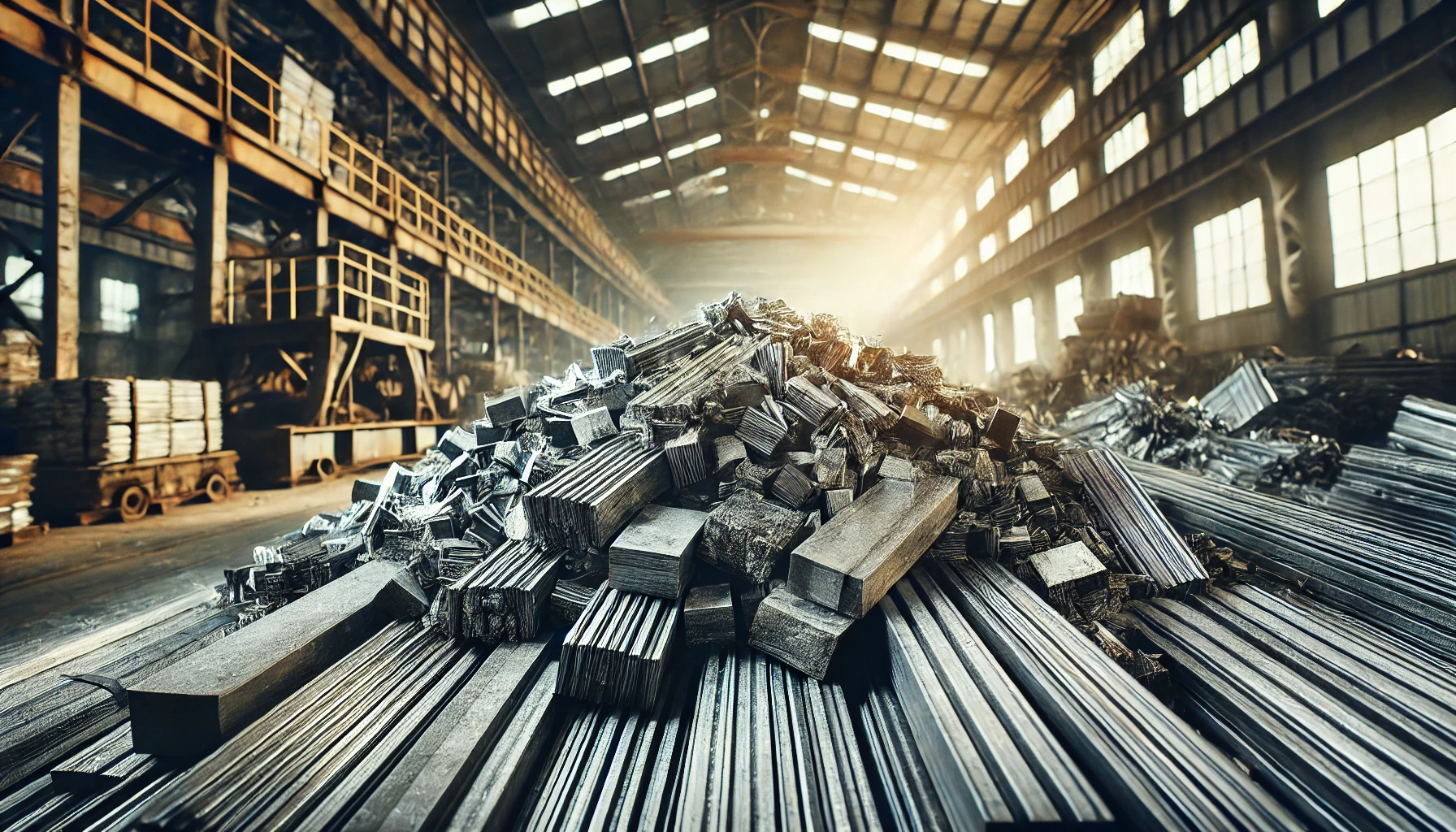

KraMet produces high-quality secondary raw materials that meet strict industry standards and are ideal for the needs of various industries. We offer recycled metal products that combine reliability, environmental responsibility and affordability. With our recycling technologies, customers receive quality raw materials that help reduce costs and reduce their carbon footprint.

KraMet recycled steel is a material that fully meets modern requirements for quality, strength and durability. Made from carefully processed scrap metal, our steel undergoes strict stages of cleaning and processing, which allows it to be used in a wide variety of industries.

High strength and durability 🏗️🔧

KraMet secondary steel retains all the characteristics required for construction and manufacturing tasks: high strength, load resistance and durability. Thanks to advanced recycling technologies, our steel has the same reliability as primary steel, which makes it ideal for use in building structures, equipment and mechanical engineering.

Thorough cleaning and quality control 🔍✅

Before entering production, the metal undergoes a multi-stage cleaning process, including the removal of impurities and sorting by steel type. We use innovative analysis technologies such as spectral and infrared control to ensure compliance with all standards. This approach helps ensure consistent quality and reliability of products.

Saving resources and reducing costs ♻️💰

Recycled steel allows companies to reduce material costs by providing access to high-quality raw materials at a better price than primary steel. Recycling scrap metal also reduces the burden on natural resources, making secondary steel an environmentally responsible choice for modern businesses.

Sustainable production and environmental support 🌍🌱

Using secondary steel is a step towards sustainable development and reducing the carbon footprint. The production of our secondary steel requires less energy compared to the extraction and processing of primary metal, which helps reduce carbon emissions and reduce the impact on the environment. Our company supports a cyclical recycling process so that each ton of scrap metal finds a new use and minimizes waste.

Versatility and wide range of applications ⚙️🚧

KraMet secondary steel is a versatile material that finds application in construction, automotive, equipment manufacturing and other areas. Thanks to strict quality standards and processing processes, our steel is suitable for any task where high strength and reliability are required.

KraMet aluminum alloys have unique characteristics that make them popular in many industries: lightness, strength and corrosion resistance. Manufactured from carefully recycled scrap metal, our alloys meet high quality standards and help reduce production costs while maintaining environmental responsibility.

Lightweight and high strength ✈️🔩

Aluminum alloys from our company are lightweight and highly durable, making them ideal for use in areas where a balance between lightness and reliability is required. These alloys are often used in the aerospace and automotive industries, where every kilogram of weight matters for efficiency and productivity.

Corrosion resistance and durability 💧🔧

Thanks to innovative cleaning and processing methods, KraMet aluminum alloys are highly resistant to corrosion and external factors. This makes them ideal for use in conditions of high humidity, chemical exposure and aggressive environments. Our alloys are successfully used in construction, shipbuilding and other areas where materials are exposed to external influences.

Energy-efficient production and quality control ⚙️✅

Our company uses advanced methods of melting and processing aluminum, which allows us to reduce energy consumption and reduce the carbon footprint. The entire process is carefully controlled - from the preparation of raw materials to the production of finished alloys. Our monitoring systems ensure high purity and reliability of the material, which makes it suitable for high-tech tasks.

Saving on production costs 💰🔄

Secondary aluminum alloys from our company provide companies with the opportunity to reduce raw material and production costs. Due to the use of recycled scrap metal, our alloys are cheaper than primary aluminum, while maintaining similar strength and reliability indicators. This allows our customers to effectively manage costs and improve production economics.

Reducing the ecological footprint and supporting sustainable production 🌱♻️

KraMet's aluminum alloy production helps reduce the burden on natural resources by reducing the need for primary aluminum mining. We use secondary raw materials and adhere to environmental standards, which allows our customers to support sustainable development. Aluminum recycling requires 95% less energy compared to primary production, making our alloys an environmentally friendly solution for business.

KraMet copper granules are created from recycled scrap metal, ensuring high quality and affordability while supporting sustainable production. With excellent electrical conductivity and purity, our copper granules are ideal for a variety of applications in the electrical and cable industries.

High electrical conductivity and quality stability 🔌⚡

KraMet copper granules have high electrical conductivity, which makes them indispensable for the production of cables, wires and other components where reliable transmission of electrical current is required. Due to the careful cleaning and sorting process, our granules provide stable electrical properties, which makes them a reliable choice for equipment manufacturers.

Thorough cleaning and sorting 🔍✅

We use a multi-stage cleaning and sorting process, which allows us to produce copper granules that meet high quality standards. Using infrared and spectral analysis, we ensure that each batch of granules is clean and free of impurities that can reduce conductivity and durability. This increases the efficiency of the final product and simplifies production processes.

Economical and environmentally friendly solution ♻️💰

KraMet copper granules reduce material costs, as production from recycled raw materials is cheaper than using primary copper. At the same time, the quality and properties of the material remain at a high level. This makes our granules an economically advantageous solution for companies seeking to manage production costs and maintain high standards at the same time.

Supporting sustainable production and reducing carbon footprint 🌍🌱

The production of copper granules from recycled raw materials reduces the need for primary copper mining and processing, which helps to reduce the carbon footprint and reduce the burden on natural resources. We adhere to an environmentally responsible approach to recycling, which allows our customers to become part of a sustainable supply chain and reduce their impact on the environment.

Flexibility and versatility of application ⚙️📦

Copper granules from our company are suitable for use in a wide variety of areas: from the production of cables and electrical components to complex power transmission systems. Their high electrical conductivity and resistance to external influences make them ideal for any production where copper is used as a conductive material.